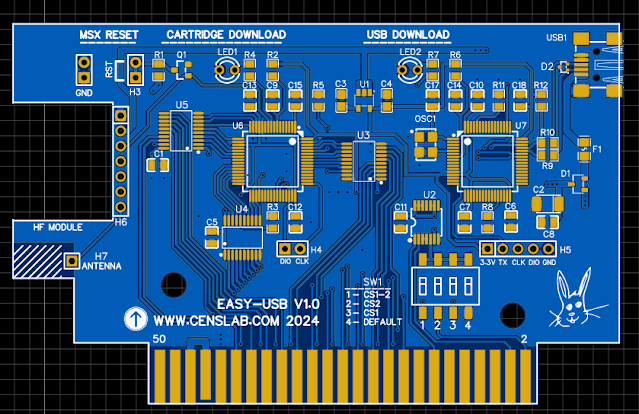

I made two final changes to the design of this cartridge.

First modification.

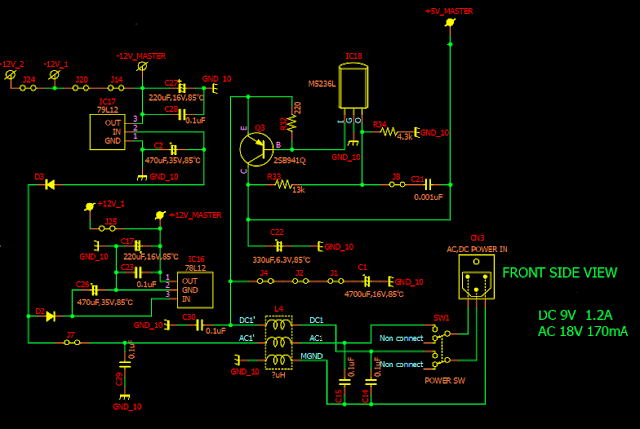

The first concerns the interfacing circuits with the MSX bus : Aoineko, the developer of the MSXgl graphics library who also tests the cartridge, reported to me problems with random startup of his computer. After studying his problem and especially after looking at the datasheet of his Panasonic FS-A computer, I realized that the power supply of this machine was 'unconventional' to say the least. This results in potential ground problems :

I guess you 'see' what I mean. The wire that serves as a ground reference is one of the two wires of an AC power supply! Hmm, I don't like that at all.

With this type of design, the ground is always noisy for anyone who wants to connect to this type of device by taking the electrical reference of this ground.

I therefore powered the cartridge interface circuits no longer directly with +3.3V via the cartridge's internal regulator, but directly via +5V from the MSX computer. No no, the problem was not a bad adaptation of the signal thresholds. TTL circuits work very well with commands not in +5V but in +3.3V. The HIGH level must be at least 2V, which is the case. On the other hand, it is true that this leaves a noise margin of 'only' 1.3V in the case of supplying the interface circuits with 3.3V, and given the design of the Panasonic FS-A1 power supply, I tell myself that that's a bit fair.

Very good, but then I just postponed the problem elsewhere? It's true. But the interface circuits used, even if they can be powered by 5V, still accept signals coming from circuits powered by 3.3V. The minimum voltage for a high signal is 1.7V on these circuits. I therefore gain 300mV of noise margin. I hope this will be enough.

I still purchased a USB bus isolator in case my modification does not work on the Panasonic FS-A1. This will at least validate my 'theory'.

Second modification.

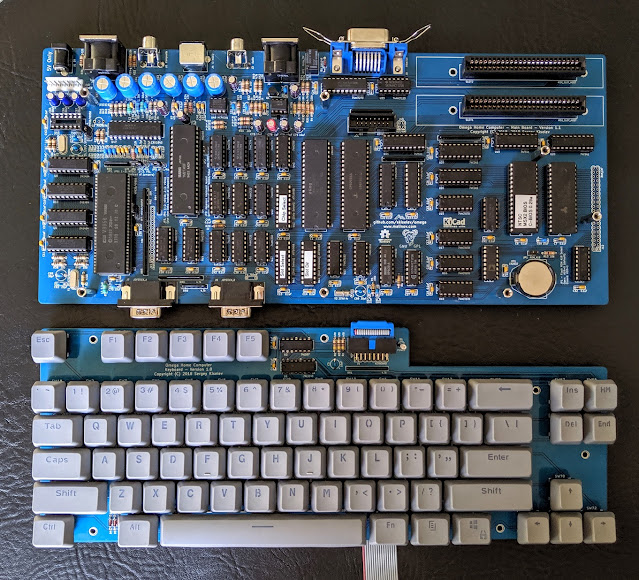

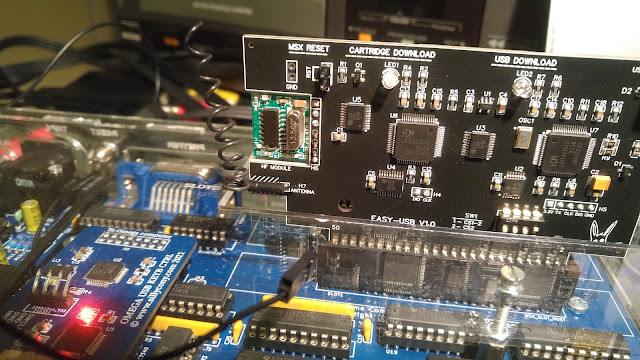

This time, it is the automatic RESET system of the MSX computer. I implemented directly on the cartridge, a system which allows the computer to be placed in RESET mode for the duration of the cartridge loading. In doing so, and once the cartridge has been loaded correctly, the MSX computer wakes up and boots directly from the cartridge : great!

The small 'problem' of this solution is that it is necessary to intervene inside the MSX computer to locate the reset system, in order to connect the RESET 'wire' coming from the cartridge.

This is a very simple operation to carry out for those who know how to do it, but this is not the case for everyone. The solution then consists of finding a way to turn off the power to the MSX computer and then turn it back on once the cartridge has been loaded. Without using any wired connection because it is too dangerous. So I opted for a wireless solution.

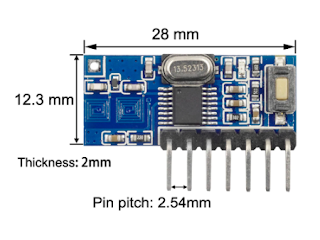

I bought some small 433MHZ modules:

These models are simple enough to use and small enough to be integrated without major modification on my cartridge.

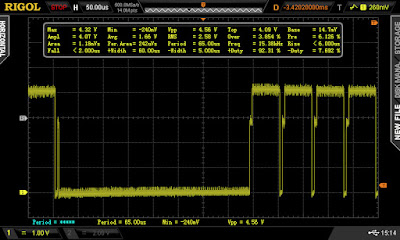

And there you have it... The first tests were functional. I was able to easily turn on and off a small LED connected to a receiver module placed a few meters away.

The receiver module:

To finalize the subject, all I have to do is develop the receiving system. It will simply appear in the form of a remote controllable mains socket. However, I use universal AC outlets so it can be used just about anywhere :

This circuit is simple and easy to assemble. I also think I will use it not only for the type of application targeted here, but more simply as a remote-controlled socket. You can easily find small remote control 'keys' on the Internet that will work very well with this HF receiver.

Warning :

The HF systems and the design of the cartridge have not been the subject of any certification request. However, the transmission power in games is so low that this does not pose a problem. However, not to be used in a sensitive environment such as healthcare centers....